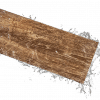

Concreate® Metal Grey Floor Panel | CF108

POA

Rich steel blue and grey tones create an industrial steel aesthetic ideal for a contemporary design scheme.

Natural marks, blemishes, scratches and dents enhance the industrial feel of these large air-cured nature fibre cement floor tiles. The top layer, which features a bevelled edge, is bonded to an ultra-hard, lightweight mineral cement base layer with a Tongue and Groove fitting profile for easy installation.

The top layer is sealed with a high solid Danish oil creating a durable, stain-resistant and more sustainable alternative to traditional poured concrete or heavy slabs.

These ingenious tiles create a heavy industrial aesthetic without the need for the normal extra support conventional concrete design requires.

| Area | 0.72m2 with 2 panels |

|---|---|

| Finish | Natural Oil |

| Top Layer | 4mm of fibre reinforced cement |

| Construction | 10mm non-portland cement base layer |

| Fitting Profile | Tongue & Groove |

| Tile Dimensions | 300 x 14 x 1200 mm |

Delivery

To see which delivery options are available for this product, please add the desired quantity to your Basket. In the Basket and at Checkout, you will see which options are available to you.

If you do not see a delivery option e.g Next Day and only see the Free Delivery option, this means we cannot offer express delivery at this time for your order.

Our standard delivery is 2-6 Working Days.